PICS OF TANK GAUGES, DATA PLATE & REGULATORS

TANK GAUGE

TANK GAUGE

Twin stage regulator

Picture of the pressure gauge reading from 5 % to 95%. This is the typical pressure gauge on a propane tank, although some may vary and may indicate gallons instead of percent.

Twin stage regulator

High presssure regulator

Twin stage regulator

Pic of twin stage tank regulator, which reduces the tank pressure from 250 psi to 11 inches water column-roughly 6 ounces pressure, which is the pressure that household gas appliances are designed to operate at.

High presssure regulator

High presssure regulator

High presssure regulator

Pic of high pressue regulator which typically reduces 250 psi tank pressure to 10 lbs which is the pressure needed to supply gas systems with higher pressure from the tank to the second stage regulator, which typically enters the structure.

2nd stage regulator

High presssure regulator

High presssure regulator

Pic of 2nd stage pressure regulator which reduces pressure from 10-20 pounds to appliance pressure: 11 inches water column, typically installed at the structure in larger propane systems.

frequently asked questions

Q: Why do I have to have a leak test performed on my propane system?

Q: Why do I have to have a leak test performed on my propane system?

Q: Why do I have to have a leak test performed on my propane system?

Leak tests are required any time there is an interruption of service meaning the flow of gas was stopped for any reason. NFPA 54 (2006), 8.2.3 states that "Immediately after the gas is turned on into a new system or into a system that has been initially restored after an interruption of service, the piping system shall be tested for leakage. If leakage is indicated, the gas supply shall be shut off until the necessary repairs have been made".

The leak test will indicate any leaks within the propane piping system. The leakage test is simply testing the integrity of the system plumbing joints and the seal of the pipe joint compound. This is the safety reasoning behind leak testing. To reiterate, the pressure test is performed in order to ensure the safety of the home owner/business owner.

All propane piping, connections, and fittings are threaded so that they may easily connect together during installation or modification. These propane connections are coated with a pipe joint compound that lubricates the fittings during the joining process and will dry after a short while. During normal usage, a propane plumbing system is at a constant pressure. This means that as long as the tank has gas and is supplying the system with propane, a constant pressure is exerted on the piping and joint compound. The pipe joint compound will expand during normal pressurized usage and will retract if the system loses pressure. The loss of gas pressure may cause leaks to form because of the expansion and retraction of the piping compound within the propane plumbing system.

Q: I need a propane tank but don't know if I should rent or buy one?

There are pros and cons for both the rental and purchase of propane tanks that should be taken into consideration when deciding between buying a tank or leasing one.

Leasing:

Company owned tanks are maintained by the propane company so any repairs to the tank will generally be taken care of by the company. All propane must be purchased from the company that owns the tank.Tank contracts often give the company the legal right to enter property to inspect the tank. Many providers require a minimum annual propane usage or a certain number of propane appliances in the propane system. Moving to a new home will require you to notify your propane company of your relocation.

Purchasing:

The initial cost of purchasing a tank can be expensive as opposed to yearly rental fees for tank leases. Warranty on tank, parts, and labor should be considered prior to purchase (typically warranties are short term). Customers can purchase propane from which ever gas company they choose. Here at Pacheco Oil & Gas Inc., we require a minimum yearly consumption of propane to rent a propane tank. The following conditions apply for tank rentals:

120 Gallon Tanks - Minimum yearly consumption of 400 Gallons (Mora area only)

250 Gallon Tanks - Minimum yearly consumption of 500 Gallons (Any area we service)

500 Gallon Tanks - Minimum yearly consumption of 1,200 Gallons (Any area we service).

Q: Is propane safe? Do propane tanks explode easily?

Q: Why do I have to have a leak test performed on my propane system?

Q: Why do I have to have a leak test performed on my propane system?

This question has been asked of many propane dealers and is also a topic discussed by people that are unfamiliar with propane. Although Propane tanks can explode or rupture, it is extremely rare that an explosion would occur. In fact, for a propane tank to reach the point of explosion, there must be a tremendous amount of heat for an extended period of time. Many people believe that a propane tank "explosion" can occur with the slightest of ease. However, this is simply not true and people should understand that a propane tank, when operating under normal circumstances will not explode or rupture. Safety devices and mechanisms are in place to prevent explosions, accidents, and propane tank ruptures or breaches. Just like any other hazardous material or activity, human error is a primary factor in preventing or contributing to any type of accident, however serious in nature.

Q: How do I select a propane provider?

A: When selecting a propane provider, the following criteria are important:

Safety Record - Ask the company about their safety record and safety programs. They should be able to offer references, such as regulatory agencies that will attest to their safety record as well as any safety programs they are enrolled in or perform within their organization.

Regulatory Agencies - Each state has an agency regulating its propane industry. These agencies and regulatory commissions oversee all activities regarding the LP Gas Industry within their respective state. Although state regulators probably can't recommend any particular propane company, they may be able to provide information about safety records and compliance if requested. Company Policies - Ask about any policies such as out of gas procedures, service fees or pricing structures that may work better for your budget and give you peace of mind. Although some companies charge additional fees such as Hazmat and Fuel Surcharge Fees for deliveries in addition to the price quoted per gallon, Pacheco Oil & Gas, Inc. does not have any such charges. Also, companies vary on hourly rates for service work, tank lease/rental fees, and fees for gas leak tests.

The very best advice is to choose a company based on their references, reputation, and safety record...not solely their price. Your safety and that of your family depends on it.

Q: I've never used propane before. What do I expect? Who do I call?

Q: Why do I have to have a leak test performed on my propane system?

Q: I've never used propane before. What do I expect? Who do I call?

If you have recently purchased or rented a property that has a propane system, determine if the property has a propane tank. If it does, check the tank for stickers that identify a propane gas company. Some companies have tags or stickers underneath the dome at the top of the tank. This will give you an indication of who (what company) is familiar with your propane system. Most propane companies keep records of tanks they service by location and the tank's serial number.

The following items can be found on a typical propane tank manufacturer nameplate (located under tank dome):

Necessary Name Plate Markings

In addition to the nameplate being visible and permanently attached to the tank, the following must be displayed:

1. container designed for service type(above or underground)

2. tank manufacture name and address

3. tank water capacity typically in gallons

4. design pressure (working pressure) in PSI

5. words " This container shall not contain a product that has a vapor pressure in excess of 215 PSI at 100 degrees Farenheit

6. outside surface area in square feet

7. year of manufacture

8. tank shell and head thickness

9. OL (overall length), OD (outside diameter), and HD (head design)

10. tank manufacturer's serial number

11. ASME code symbol

Typical Manufacturer's Nameplate is shown at top of this column.

- ASME code symbol: If you are able to locate a sticker/tag identifying a propane gas company, this indicates that the tank is likely owned by that company. You will need to contact the company to determine a course of action for either obtaining service from them or having them remove the tank. If a propane tank is leased from a propane gas company, that company is the ONLY propane provider that may service that tank. If you determine that you own the tank, the owner can then contact any propane gas company they choose for service.

Q: Where can I place a propane tank for service?

In order to ensure that you are in compliance with national statutory codes, it is best to contact a licensed propane service provider to inquire about acceptable locations for tank sets. Certain clearances are required for tank sets depending on the size of the tank and the proximity to structures, property lines, electrical boxes, and other important criteria. National codes have been established depending on the size of the propane tank and in some cases local jurisdictional codes may supersede some national requirements. Therefore, to save yourself headaches, time, and money, it is in your best interest to contact a licensed propane provider to ensure the latest code requirements are met.

Q: Is my tank or propane system leaking?

Propane tanks will sometimes give an indication of a leak by sound or by smell. People will describe this noise as a "hissing" noise coming from the tank getting louder as they get closer. In addition, a rotten egg smell will often accompany the "hissing" noise. In many instances, the tank may be operating normally even though it appears to be leaking. When the amount of gas in tanks is low, the rotten egg smell will be noted inside the home as well.

RELIEF VALVE ACTUATING

RELIEF VALVE ACTUATING

Q: I've never used propane before. What do I expect? Who do I call?

On extremely hot days when the sun is high overhead and a propane delivery has recently been made, the safety relief valve may open slightly allowing excess pressure to vent. If the relief valve is opened, the rubber cap will be removed from the top of the valve from the pressure buildup, as pictured above. DO NOT LOOK INTO THE RELIEF VALVE OR TAP IT WITH ANYTHING. Doing this may cause the relief valve to open all the way. The relief valve is doing what it is designed to do: releasing excess pressure from the tank. One way to remedy the situation is to cool the tank down by spraying water from a water hose on the tank surface. This will gradually cause the valve to close.

REGULATOR RELIEF VENT

RELIEF VALVE ACTUATING

REGULATOR RELIEF VENT

The regulator vent allows the regulator to "breathe" during normal operation and functions as a pressure relief opening in an excess pressure situation. It should remain free of dirt and debris in order to operate properly. Propane regulators are manufactured with pressure relief devices built inside the regulator body and operate in a similar manner as that of a tank pressure relief valve. If triggered, the relief valve will open and allow gas to escape through the regulator vent.

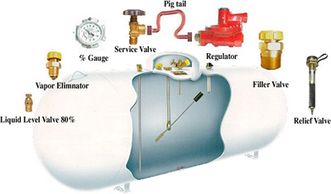

PROPANE TANK PARTS

RELIEF VALVE ACTUATING

REGULATOR RELIEF VENT

Propane tanks need periodic replacement of parts. Regulators, depending on the manufacturer, have to be changed out every 20 or 25 years as per code. At Pacheco Oil & Gas, we change out tank relief valves 35 years after the date of manufacture. The remainder of tank parts are changed out as needed, with no specific change out dates.

safety

Copyright © 2024 Martinez Propane Inc. - All Rights Reserved.